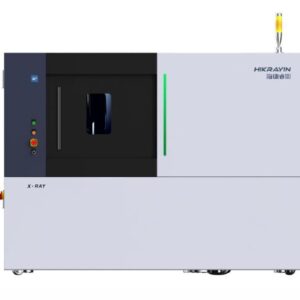

Description

ISD-NIX59-A32

Flaw Detection System

The ISD-NIX59-A32 Flaw Detection System utilizes advanced X-ray Computed Tomography (CT) technology for precise flaw detection in various materials. This high-precision system rotates the sample, capturing X-ray signals from multiple angles and digitizing them to create detailed cross-sectional images. The collected 2-dimensional digital radiography (DR) data enables the system to identify defects with exceptional accuracy. With cone beam technology, the system can gather multiple cross-sections simultaneously. A high-performance CPU reconstructs these images into a 3D stereoscopic view (3DCT), allowing for thorough analysis and measurement of any detected flaws, ensuring comprehensive quality control and inspection.